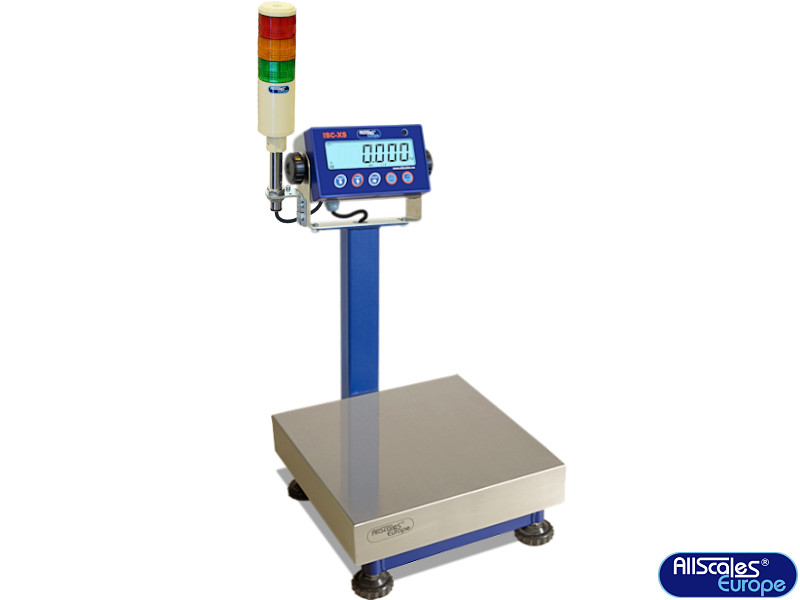

Checkweigher CW-100

Compact, reliable and accurate +/- checkweighing systems. Particularly suitable for integration in production and / or shipping conveyor systems.

Efficient and rapid static or dynamic weight control on outgoing product lines. Frame version in painted steel or optional stainless steel IP 65. Weighing functions, dimensions, conveyor belt (s), accessories, etc. in consultation.

See further under the tab Product information.

-

Type: CW-100-800-6 Weighing capacity: 6 kg Division: 2 g Version: Verified Belt dimensions: 800 x 500 mm Price: On application

-

Type: CW-100-800-15 Weighing capacity: 15 kg Division: 5 g Version: Verified Belt dimensions: 800 x 500 mm Price: On application

-

Type: CW-100-800-30 Weighing capacity: 30 kg Division: 10 g Version: Verified Belt dimensions: 800 x 500 mm Price: On application

-

Type: CW-100-1000-15 Weighing capacity: 15 kg Division: 5 g Version: Verified Belt dimensions: 1000 x 650 mm Price: On application

-

Type: CW-100-1000-30 Weighing capacity: 30 kg Division: 10 g Version: Verified Belt dimensions: 1000 x 650 mm Price: On application

Checkweigher CW-100

Features

- static or dynamic weighing of pre-packaged products, either automatically or semi-automatically by operator

- management of the conveyor-belt cadence, for optimising the number of packages per minute weighed by the instrument (cadence belt not included), through cadence photo cell (optional)

- adjusting the density coefficient for each article during weighing in ml

- programmable alarm function and tolerance indication time

- tolerance check:

- upon target, through article database, with setting of 3 tolerance thresholds, for the physical division of the packages into 7 different groups

- upon programmable weight thresholds (min/max), with article database

- upon weight thresholds (min/max), with quick entry function

- printout with each executed weigh with eventual automatic storage in the alibi memory

- automatic printout and clearing of the partial total after a programmable number of weighings

- static or dynamic automatic zero function of the belt (up to 2% of the capacity) after a programmable number of weighings

- management of the automatic rejection through its specific relay contact (rejector not included), or downtime of the belts for manual rejection or weight correction

- possibility of connection to RS485 network or ethernet

- programmable preset tare and enabling delay of the rejection for each article

- automatic calculation of the weighing time and pack positioning, for optimising the functioning of the system

- database of 1000 articles, with programmable alphanumeric description, density, targets, tolerance thresholds, and preset tare for each article

- selection of the article through bar code reading

- advanced bar code management, with the possibility of storing, processing, and printing 5 different codes

- configuration and calibration of the instrument through the tool on the PC

- report with date and time of cycle beginning and end with statistics of the checks and/or activities, standard deviation of the executed weighings, and totals by class and/or article

- possibility of connection to a control light

Technical data

- equipped with panel indicator, model VPI-Ultra (with firmware version FW-CW)

- graphic backlit display with clearly readable data such as weight, automation status, etc.

- date / time, alibi memory, data memory permanently, even during power failure

- keyboard as desired customizable by programmable key functions

- bearing structure and frame in painted steel or in extra thick stainless steel

- loading platform with motor driven conveyor mat, with adjustable height and direction

- rear handling and positioning wheels, and adjustment and fixing feet

- adjustable weighing belt speed: from 8 to 25m/min, max 25 PCS/min (higher speed on application)

- electromechanical automation for belt command and 6 auxiliary relays (up to 5A 220V)

- fitted with pack presence and weigh end photo cells (for dynamic weighing), with adjustable reading distance

- overall switch, emergency button, start/restart button, optical/ acoustic alarm (in painted steel versions)

- easy to consult backlit LCD graphic display, with clear visualisation of the weight and automation status; selection of the language from the menu

- selection of the data (totals, progressives, weight, etc.) shown on the graphic LCD display

- waterproof 25 key numerical-functional keyboard, which allows to easily enter the target, alphanumeric texts, codes, etc.

- IP65 protection class of the front panel, against dust and sprays

- keyboard functions completely configurable according to one’s requirements

- real time clock and permanent memory data

- built-in alibi memory, for CE-M transmission of the weight data to the PC or printer

- 240Vac 50Hz power supply

I/O section

- 8 digital inputs and 16 outputs for command switch on the line

- 1 RS232/C serial port for managing a built-in printer, or labeller

- 1 RS232/C bidirectional port for data exchange with PC/PLC

- 1 RS485 bidirectional port for network connection with other devices and communication with PC/PLC

- 1 keyboard emulation input for connection to PC keyboard or bar code reader

Options i.a.

- 8 digital inputs and 16 outputs for switching functions in the belt line

- internal or external ticketprinter or labelprinter

- photocell(s)

- rejector(s)

- barcode scanner

- frame and housing in stainless steel, IP65

Option Windows software

- PC-software for optimising the weighing cycle

- fast programming of the indicator

- checking of the status of the inputs and outputs

- transfer of the serial commands for managing the automation; fast change of the parameters

- summary by graphic presentation and insight in the weighings for obtaining the best weighing results

Technical data

- bearing structure and frame in painted steel or in extra thick STAINLESS steel

- loading platform with motor driven conveyor mat, with adjustable height and direction

- rear handling and positioning wheels, and adjustment and fixing feet

- adjustable weighing belt speed: from 8 to 25m/min, max 25 PCS/min (higher speed on application)

- electromechanical automation for belt command and 6 auxiliary relays (up to 5A 220V)

- fitted with pack presence and weigh end photo cells (for dynamic weighing), with adjustable reading distance

- overall switch, emergency button, start/restart button, optical/ acoustic alarm (in painted steel versions)

- easy to consult backlit LCD graphic display, with clear visualisation of the weight and automation status; selection of the language from the menu

- selection of the data (totals, progressives, weight, etc.) shown on the graphic LCD display

- waterproof 25 key numerical-functional keyboard, which allows to easily enter the target, alphanumeric texts, codes, etc.

- IP65 protection class of the front panel, against dust and sprays

- keyboard functions completely configurable according to one’s requirements

- real time clock and permanent memory data

- built-in alibi memory, for CE-M transmission of the weight data to the PC or printer

- 240Vac 50Hz power supply

I/O section

- 8 digital inputs and 16 outputs for command switch on the line

- 1 RS232/C serial port for managing a built-in printer, or labeller

- 1 RS232/C bidirectional port for data exchange with PC/PLC

- 1 RS485 bidirectional port for network connection with other devices and communication with PC/PLC

- 1 keyboard emulation input for connection to PC keyboard or bar code reader

Scale types: Checkweighers Tested: CE approval prepared Application: Industrial Scales